Recent Projects

Visit us on facebook, twitter and youtube to see more pics and videos of this and share some of your ideas and comments on this project.

Engineering Training

Some of the courses we offer include training on

- PLC (Programmable Logic Controllers)

- SCADA(Supervisory Control and Data Acquisition)

- Instrumentation, Calibration and Sensorics

- Trouble shooting

- Repairs and Maintenance

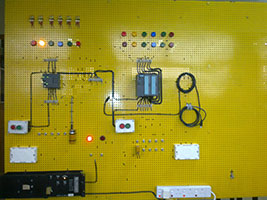

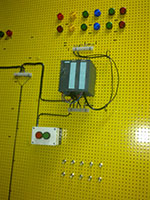

PLC Training

Companies worldwide use PLCs, HMIs and Scada to control and manage all sorts of manufacturing processes:

Power, Conveyor Control systems etc.

Unlike the inflexible Relay based Control Panels designed to only address a specific function, a PLC/HMI system is flexible so it can meet any requirement and adapt quickly by modifying its programming.

PLC Training will allow engineers to become more proactive when faced with a situation, whether it is a breakdown or needing to modify a process to increase output or manufacture a new product.

It allows them to understand how to monitor process performance and provide information on efficiency, identify process problems to reduce downtime and so much more as your business grows and changes.

So why should you invest in PLC training?

In our highly technology based 21st century, PLC training gives you the tools they need to ensure you can function efficiently and safely with PLCs.

All of our training courses cover various engineering disciplines such as how to use software development tools, write control software, maintain and diagnose manufacturing problems through the use of a PLC and also creating operator & monitoring controls on HMIs.

We can also train anyone on how to Fault Find, Modify, Debug Programs, how to cope with DISASTER RECOVERY and how to work with PLCs to Industrial Standards in the Automotive - Oil & Gas - Chemical - Airports - Component Assembly - Paper and other industries worldwide.

Also learn about:

- PLC Hardware, IO Tables, how to use a support tool, Ladder Programming with

- Normally Open or Normally Closed Contacts.

- The PLC Scan and its effects on Registers

- Single Scan signaling

- Instruction types - MOV - CMP - ADD - SUB - MOVB etc.

- Structuring of a PLC program, adjusting Timers and Counters

- Subroutines

- Interlocking and Working with Integers, Binary, BCD, Floating-Point Data Memory Areas and much more.

- Fault finding and Troubleshooting a PLC

Audience: Engineers, Electricians, Maintenance and all those who want to be updated on the latest developments in PLC systems and want to get a solid appreciation of the fundamentals of their design,usage, installation and troubleshooting..

Advanced PLC and SCADA Training

This control systems technology course is designed to benefit you with practical up-to-date information on the application of PLC systems to the automation and process control industries. It is suitable for people who have little or no exposure to PLCs (programmable control systems), but expect to become involved in some or all aspects of PLC installation. It aims to give practical advice from experts in the field, to assist you to correctly plan, program and install a PLC with a shorter learning curve and more confidence.

SCADA has traditionally meant a window into the process of a plant and / or a method of gathering of data from devices in the field. Today, the focus is on integrating this process data into the actual business, and using it in real time. In addition to this, today's emphasis is on using Open Standards, such as communication protocols (eg IEC 60870, DNP3 and TCP/IP) and 'off-the-shelf' hardware and software, as well as focusing on keeping the costs down. PLCs continue to gain in popularity. In fact, many SCADA applications use PLCs as the RTU of choice, when communicating with field devices.

This comprehensive course covers the essentials of SCADA and PLC systems, which are often used in close association with each other. A selection of case studies are used to illustrate the key concepts with examples of real world working SCADA and PLC systems in the water, electrical and processing industries. This course will be an excellent opportunity to network with your peers, as well as to gain significant new information and techniques for your next SCADA / PLC project. Although the emphasis of the course will be on practical industry topics highlighting recent developments, using case studies, the latest application of SCADA, PLC technologies and fundamentals will be covered. The workshop is aimed at those who want to be updated on the latest developments in SCADA and PLC systems and want to get a solid appreciation of the fundamentals of their design, installation and troubleshooting.

Audience: Engineers, Technicians, Maintenance Personell and Plant Supervisors and all those who want to be updated on the latest developments in SCADA and PLC systems and want to get a solid appreciation of the fundamentals of their design, installation, usage and troubleshooting..

Instrumentation, Calibration and Sensorics

This training course familiarizes students with common industrial instrumentation systems and teaches them to setup, calibrate, and troubleshoot common sensors, transducers, and instrumentation systems.

This training course uses a variety of sensors and transmitters and calibration equipment to explain and demonstrate key concepts.

Target Audience: Operators, Electricians, Technicians, Engineers, and Managers

Training Equipment: Miscellaneous temperature, pressure, level, sensors and calibration equipment; Fluke meters

Typical Course Topics (partial listing of topic areas, not in sequence):

- Parts of the typical control loop

- Process & Instrument Diagrams (P&ID's)

- Commonly used process control signals

- Signal quality terminology (accuracy, linearity, span, etc.)

- Understanding purpose of standards (NIST, etc.)

- Understanding the 4-20 milliamp current loop

- Signal conversions

- Calibration basics

- Position and speed sensors

- Temperature sensors (Thermocouples, RTD's, Thermistors, etc.)

- Pneumatic and hydraulic pressure concepts

- Pressure, force, and strain sensors

- Level detectors

- Fluid and gas flow concepts

- Flow sensors

- Typical problems in instrumentation systems

- Smart instruments

- Common Instrumentation networks

- Troubleshooting instrumentation systems

Troubleshooting Training

learn to troubleshoot all types of electrical circuits and equipment with safe hands-on practice on realistic electrical simulations using adanced simulation softwares.

Learn about the principles of Systematic troubleshooting and debugging

Repairs and Maintenance Training

We provide excellent training on all levels of Repair and maintenance to ensure that the learner is confident enough to perform safe, accurate and quality repair and maintenance of all electronic and mechanical equipment.

Ensuring quicker lead times between problem identification and correction

At Nerokas We are commited to making your life easier and more economical. Call us now for further information